Straight Tuck End Boxes

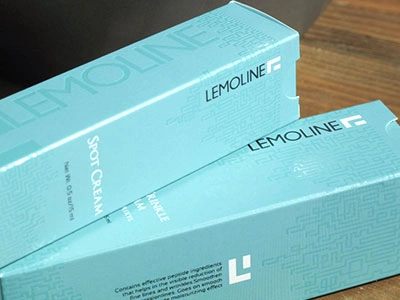

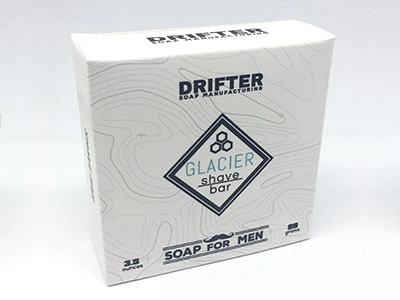

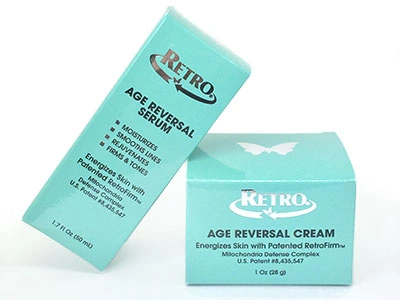

Straight tuck boxes are a very common packaging solution for a variety of industries. The box has the top and bottom closure panels attached to the same main panel. The box folds from front to back (or from back to front) in the same direction. The slit locks from each closing flap to keep the top and bottom of the box in place, securing the contents inside the box. This type of packaging is practical and offers plenty of space for information and branding.

Straight Tuck End Boxes

We could speak forever about the benefits of a straight tuck box. Just leaving here some extra advantages of this remarkable type of packaging:

- You can print on each side of the straight tuck box, which adds plenty of space for branding

- It places the front panel fully on display, which is super helpful on the shelf

- The clean edges make it look more luxurious

- You can insert the product from the top or the bottom of the box

- It is easy to assembly and can be stored in any place

Straight tuck boxes are one of the most popular types of packaging on the market. Both the manufacturers and the clients love them. The reason? They look and feel familiar, and they offer a great unboxing experience.

Their closure and endless possibilities for customization make them optimal for all types of products. Our portfolio includes straight tuck boxes for:

- Soap packaging

- Cream Packaging

- Confectionery Packaging

- Marijuana Packaging

- Perfume Packaging

- Makeup Packaging

Although they became a standard on the market, each box is unique and brings something new to the game. Enrich your customers’ experience with a straight tuck box!

Find Your Box

Enter your dimensions (in inches), hit search and scroll down for you results.

Your Box, Your Label, Your Way.

We have all the equipment in place to make your box shine. From sustainably created paperboard to coatings and finishes that make your product stand out.

Quality Product & Service

Environmentally friendly

Fast & cost-effective

Made in the USA

Fast & Reliable Shipping

Get Started Today

Get started on your template or give us a call to talk to our experts.